A rectangular cold box consists of a steel frame with panels of sheet metal. Fives is a pioneer with more than 60 years of industry-leading expertise in cold box design production installation and.

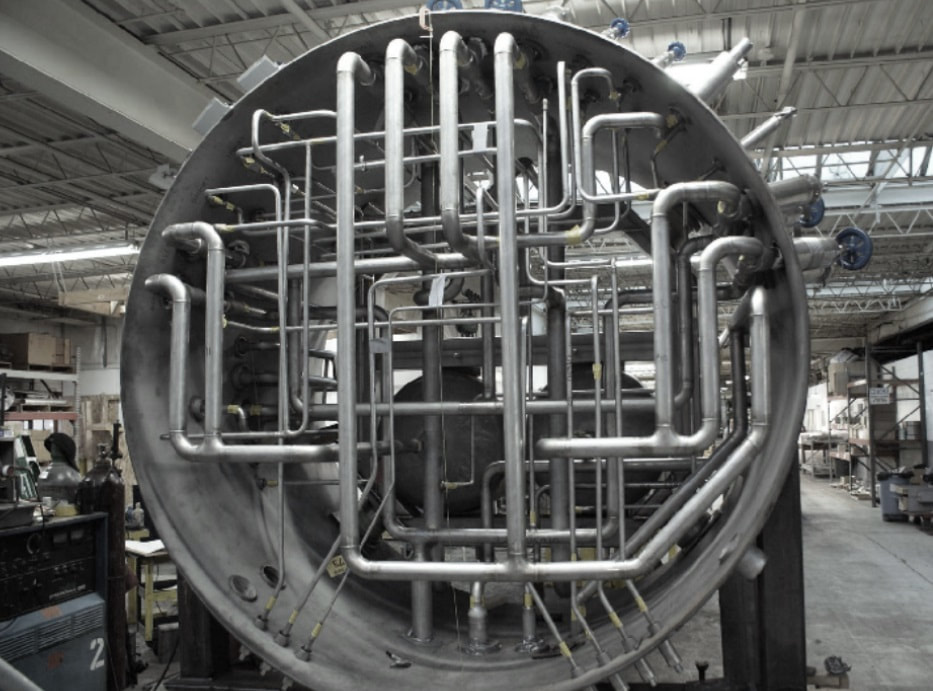

Custom Cryogenic Distribution Boxes And Cold Boxes Meyer Tool Mfg

The cold box containing all cold equipment is designed considering strength and thermal aspects.

. This design is generally used in throttling andor isolation control of cryogenic liquids and gases. This requires extremely reliable cryogenic equipment including valves able to. Optimal cryogenic cold box design thanks to decades of experience Fives is a pioneer with more than 60 years of industry-leading expertise in cold box design production installation and maintenance.

During construction the Perlite is installed before any liquefied gas enters the inner tank. Component layout inside the chamber is decided to maintain a temperature gradient through the length of the chamber. A Chart BAHX is a highly efficient all brazed and welded compact heat exchange device that offers distinct advantages versus other heat exchanger types.

Read customer reviews find best sellers. We design cryogenic columns in line with our own hydraulic layout or to customer specifications. Our in-house engineering team provides process instrumentation pressure vessels distillation column internals equipment layout.

The accumulator cold box Q1212 W. Super cold or extremely cold cryogenic fluids such as hydrogen and helium are normally stored in spherical double-walled vessels with perlite-filled annular spaces. We have delivered over 350 units worldwide to natural gas industrial gas and petrochemical processing plants.

Cryogenic Grade Perlite is transferred into the void by a pneumatic pump combined with conveying pipes. To a cryogenic system At pressures near 1 Atm the heat transfer is by natural convection At lower pressure convection is reduced but gas conduction still can transfer considerable heat k T. The cold-box is made in segments that include the outer shell upper column lower column main condenser argon columns and boxes for heat exchangers and expanders.

A single column can measure up to 7 m in diameter be up to 45 m long and weigh up to 170 tons. So the chamber can be thought of two chambers. Storage temperatures of -150F -100C and above to 40F 4C are considered low temperature.

Acceptance test of helium refrigerata ion cold box system for the Cryogenic Testing Facility CTF at Thomas Jefferson National Accelerator Facility also known as Jefferson Lab or JLab in Newport News. The leakage of two cold boxes meet the design requirement. Process is extremely cold so akey feature of cryogenic distillation is effective cold box insulation which is typically achieved using perlite.

Two cold boxes are winded with multilayer insulation to reduce heat leakage the vacuum need to reach more than 133 10-2 Pa. CRYOGENIC SPECIFICATIONS Extended Bonnets Extends valve packing and operator away from cryogenic fluid Allows operation in normal working temperature range Cast forged or fabricated with seamless tube Minimum extension lengths for non-Cold boxCold box applications based on valve type NPS and temperature design to worst case ASME B1634. However the term cold box is sometimes used to refer to all enclosures regardless of cross section shape.

Components that exceed these dimensions are welded at Linde workshops near harbours or directly on site. Cold Box Package Storage temperatures of -150F -l00C and below are considered cryogenic. The walls can be up to 70 mm thick.

Mineral wool was used for insulation prior to the late 1940s. Andso too all natural condensations caused by cold should be investigated in order that their causes being known they may be imitated by art. Cylindrical cans with insulation are also used in certain applications.

35 Cryogenic Cryogenic processes operate at temperatures below approximately -90C -130F from EIGA Doc 146 10. When designing cryogenic systems the designer is faced with conflicting requirements which require careful analysis to achieve optimum results. They are transported readily and can be assembled at site under SASPG supervision.

These tanks are designed with an inner and outer tank with the insulation annulus in between the tanks filled with a Cryogenic Grade Perlite insulation. Capacity upto 2 kW at 45 K. Staff is comprised of highly skilled and experienced engineers and designers who are career-long experts in deep cryogenic system design.

Cryo Technologies vacuum cold box engineering design and fabrication expertise affords us the ability to offer our customers helium and hydrogen liquefiers of unparalleled performance and quality. The Series V817 control valve is designed specifically for use in cold box applications. The entire cold box is filled with fine granules of perlite to insulate the process vessels and piping from ambient heat.

34 Cold box and cylindrical enclosure A cold box is an enclosure containing insulation that separates a cryogenic process from the surrounding environment. This regime occurs for gas densities where the mean free path is less than the wall spacing. It is a single-seated body-guided globe style with threaded seat ring and an extended neck that allows the body to bonnet joint to be outside the cold box.

They are designed in accordance with the worlds pressure. Cold Box Design MLEA Inc. 34 Cold box and cylindrical enclosure A cold box is an enclosure containing insulation that separates a cryogenic process from the surrounding environment.

It also provides structural support for the equipment. Chart Industries pioneered the use of BAHX for cryogenic gas processing in the 1950s and weve produced over 13000 units since. Both less than 100 W.

Design of the vacuum cylinder Processing. Ad Browse discover thousands of brands. Is unique in that we provide the full range of cryogenic cold box detailed design and engineering services.

When designing cryogenic systems the designer is faced with conflicting requirements which require careful analysis to achieve optimum results. The cryogenic equipment is enclosed in an insulated enclosure termed a cold box. 05L to 50L Storage Capacity Dewars.

A 3-D visualization of a SASPG cold-box is illustrated in the accompanying diagram. Newton 1642 - 1727 Novum organum 1620 Thethird of the seven modes relates to heat and cold. Cryogenic processes require insulation to reduce heat transfer from the surrounding.

One 4 K part and another 20 K part. Turbine Brake Cooler Design 316 Cold Box Insulation System 316 Final Mechanical PartsComponent List Including Transition Joints 14. The general heat leakage of hydrogen cold box Q4395 W.

Among the most important considerations are the performance of the refrigerator ie temperature reached and maintained and the degree of vacuum achieved. And herein mans power is clearly lame on oneside.

Cold Box Sumitomo Precision Products Co Ltd

Custom Cryogenic Distribution Boxes And Cold Boxes Meyer Tool Mfg

Co Cold Box Syngas Separation And Purification Air Liquide

Cold Box Sumitomo Precision Products Co Ltd

Fives Energy Cryogenics Cold Boxes Fives Group

Cold Box Sumitomo Precision Products Co Ltd

Cryogenic Cold Box Cryocore Sme Process Solution Llc

Cold Box Installation Operation And Maintenance Chart Energy

0 comments

Post a Comment